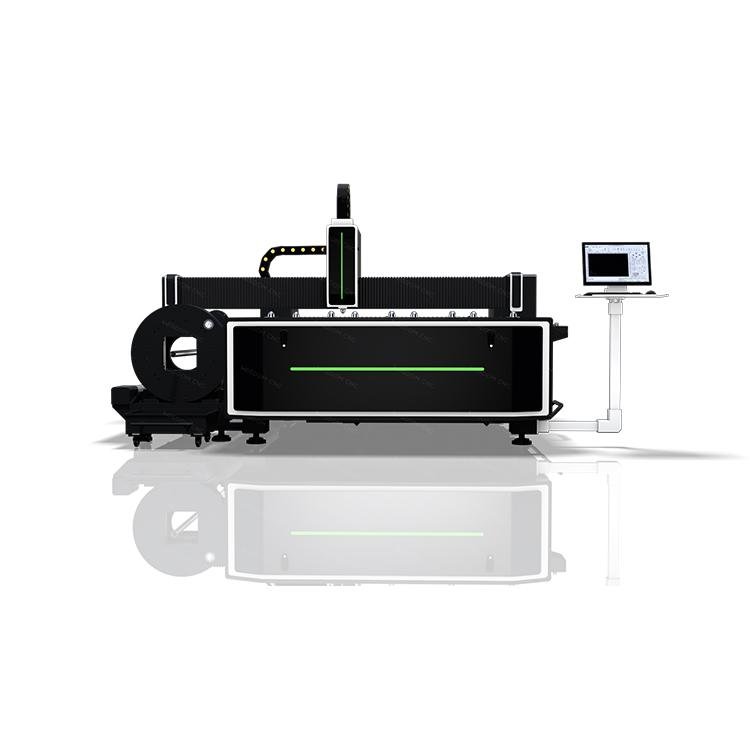

1530 Sheet Metal and Pipe CNC stainless fiber laser tube cutting machine price

Model No.︰WS-F3015R

Brand Name︰Wisdom CNC

Country of Origin︰China

Unit Price︰US $ 28000 / pc

Minimum Order︰1 pc

Product Description

Main Machine Features:

1) Excellent beam quality: Smaller focus diameter and high work efficiency, high quality;

2) High cutting speed: Cutting speed is more than 20m/min;

3) Stable running: Adopting the top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

4) High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine has three times photoelectric conversion efficiency;

5) Low cost & Low maintenance: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine. Fiber line transmission no need reflect lens, save maintenance cost;

6) Easy operation: fiber line transmission, no adjustment of optical path;

7) Super flexible optical effects: Compact design, easy to flexible manufacturing requirements.

Product Paramenters

|

Model |

WS-F1530R |

|

Cutting working area |

1500x3000mm |

|

Laser Generator |

Raycus / IPG /MAX |

|

Fiber Laser Power |

1000W/1500W/2000W/3000W/4000W/6000W |

|

Control system |

Cypcut |

|

Transmission system |

Gear + rails |

|

X.Y axis location accuracy |

±0.01mm |

|

X.Y axis repeat location accuracy |

±0.01mm |

|

X.Y axis max moving speed |

120m/min |

|

Laser wave length |

1064nm |

|

Application materials |

Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron,Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet,Tubes and Pipes. |

|

Application industry |

Manufacture Billboard, Signs, Advertising, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc. |

PRODUCT CONFIGURATION

1. Professional laser cutting head

Laser cutting head is with Z axis height adjuster. The laser head is with capacitive sensing to automatically, stably and rapidly adjust the laser head height during cutting, which ensures it cutting with the same and the best focal length all the time even if the metal sheet is not flat.

2. Raycus laser source

1. Excellent quality of laser beam, constant BP within all the ranges of laser powers, getting very small size laser spot even with long focus.

2. Special wavelength (1080nm), unique ability to cut high-reflective materials, such as aluminum, copper and brass, etc.

3. Cypcut control system

CypCut laser cutting control system integrates file reading, design, output, and processing control. It's able to complete the entire process from design to processing. The software, installed in an industrial computer, provides a wealth of laser cutting processing parameters, flexible layout and cutting path editing capabilities. Cypcut Control system and software in English language, supporting files: DXF, PLT, AI, LXD, etc. Drawing in the software is ok. Software is with fly cutting mode for cutting same products to save time. The nesting function automatically arranges graphs to leave minimum spaces and save materials.

4. Yaskawa Servo motor

We use Japanese YASKAWA servo motors and drivers. Machine X is driven by a 850W motor, Y is driven by two 850W motors, and Z (laser head auto focusing) is driven by a 400W motor.

5. Linear guide rail and rack pinion

Machine is with gear rack and linear rail transmission, which ensures machine high speed movement, precision and stability as well. 2 gear racks and 2 rails (25mm width) in Y; 1 gear rack and 2 rails (20mm width) in X. The transmission system is protected by dust shields.

6. Automatic oil lubrication

Pressing the handle above the oil box, it automatically lubricate guide rails, which ensures the machine keep moving smoothly and with good precision.

7. Rotary attachment

It allows to cut 6 meters long and 20~220mm diameter tubes (including round, oven, rectangular, H, L, U, T shape tubes). The rotary is with front and rear pneumatic chucks. 2 tube holders avoid long tube bending in the middle area.

Payment Terms︰ T/T /Western Union /DA /DP

Product Image